Microbial contamination control in feed mills

- Addtime: 2025-07-25 / View: 191

Feed safety is the cornerstone of animal health and the source of food safety. Fantong Bio has been deeply involved in the field of industrial disinfection for more than ten years. With precise detection technology, customized prevention and control solutions and long-term management systems, it has built a microbial contamination prevention and control barrier from raw materials to finished products for feed companies, helping customers achieve the dual goals of quality upgrade and risk control.

Risks and hazards of microbial contamination in feed production

Microbial contamination is hidden in the entire production process, and the threat cannot be ignored:

Raw material side: Grains, fish meal, etc. are susceptible to mold and salmonella contamination, and transportation vehicle residues cause cross infection;

Processing side: Insufficient granulation temperature leads to incomplete sterilization, residual fungi in equipment gaps, and humidity in the workshop accelerates microbial reproduction;

Personnel side: Insufficient operation protection, lack of disinfection process, and surface pathogens directly contaminate feed.

Pollution not only leads to feed nutrient loss, animal diarrhea or growth retardation, but also may threaten human health through the food chain, seriously damaging corporate reputation and economic benefits.

Fantong Solution: Accurate traceability, targeted disinfection, and long-term control

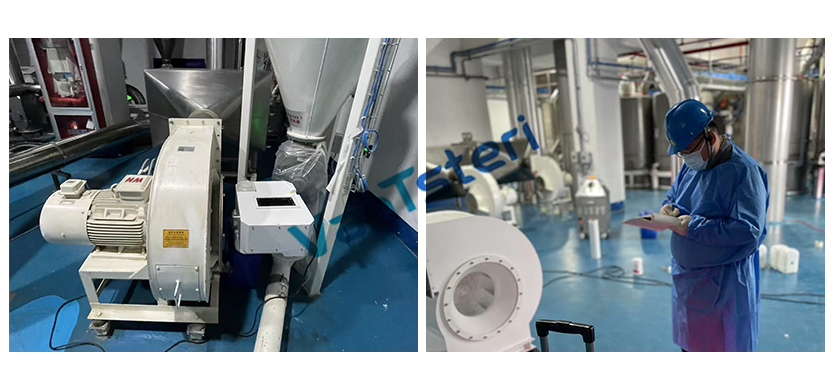

Step 1 Intelligent detection, accurate traceability

Molecular biology technology: Use 16S rRNA gene sequencing and fungal ITS sequence analysis to quickly identify pathogenic microorganisms such as Aspergillus flavus and Salmonella and toxin risks;

Three-dimensional environmental sampling: Cover key points such as raw material warehouses, processing equipment, air, and employee hands, combined with temperature and humidity big data analysis to accurately locate the source of pollution.

Step 2 Full-link targeted disinfection to prevent the spread of pollution

Efficient sterilization technology: Match internationally certified technologies such as hydrogen peroxide vaporization according to the type of pollution, penetrate equipment gaps and dust environments, and achieve a sterilization rate of ≥99.99%;

Process upgrade and optimization: Optimize granulation temperature parameters, transform equipment cleaning processes, add automated disinfection devices, and cut off the microbial reproduction chain;

Strict control of raw materials: Cooperate with suppliers to establish a microbial sampling mechanism, conduct secondary testing on high-risk raw materials (such as fish meal), and reduce pollution input at the source.

Step 3 Dynamic monitoring, long-term guarantee

Digital monitoring platform: real-time tracking of core indicators such as workshop temperature and humidity, total bacterial count, and instant warning of abnormal data;

Periodic re-inspection service: monthly inspection + quarterly in-depth inspection, dynamic adjustment of disinfection frequency and process parameters, to ensure that microbial indicators continue to meet the "Feed Hygiene Standards".

Choose Fantong Biological's four core advantages

✅ Technical hard core: 10 years of focus on feed industry disinfection;

✅ Accurate and efficient: 24-hour emergency response;

✅ Compliance guarantee: The solution complies with international standards such as ISO 22000 and HACCP, helping enterprises pass authoritative certification;

✅ Cost controllable: Reduce product scrap rate through preventive disinfection and process optimization.