Microbial contamination control in food factories

- Addtime: 2025-07-25 / View: 185

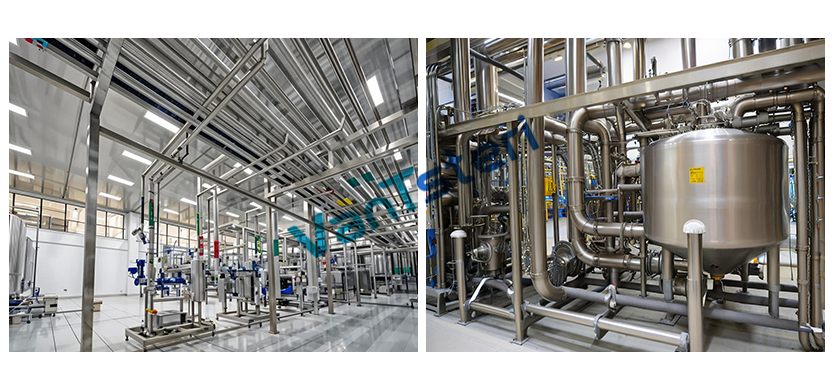

Food safety is the lifeline of an enterprise, and microbial contamination prevention and control is a race against time. As a technical service provider deeply engaged in the field of food industry disinfection, Fantong Biotechnology relies on precise detection technology and full-process intervention solutions to build a microbial contamination prevention and control system from source to terminal for food companies, helping customers achieve a win-win situation of safety and benefits.

A complete analysis of the risks of food microbial contamination

Microbial contamination lurks in every link of production, and the threat cannot be ignored:

Raw material side: soil/water source pathogenic bacteria contamination, cross-infection of transportation tools;

Production side: out-of-control of workshop temperature and humidity, equipment cleaning dead corners, and improper operation of personnel;

Storage and transportation side: insufficient sealing of packaging, fluctuations in environmental temperature and humidity lead to secondary contamination.

These hidden dangers may cause product corruption and deterioration at the least, or lead to foodborne disease risks such as salmonella and aflatoxin at the worst, directly threatening consumer health and corporate brand reputation.

Fantong Bio-Solutions: Scientific Traceability, Precise Intervention, and Long-term Control

Step 1 Intelligent detection, locking the source of pollution

Molecular biology technology: Use highly sensitive methods such as PCR and gene sequencing to accurately identify the types and concentrations of pathogenic microorganisms such as Salmonella and Escherichia coli;

Three-dimensional environmental sampling: Multi-point sampling of air, equipment surface, raw materials and finished products, build a pollution heat map, and quickly locate the source of pollution.

Step 2 Customized solution, full-link precise disinfection

Targeted disinfection design: Match internationally certified technologies such as vaporized hydrogen peroxide technology according to the type of pollution to ensure a 99.99% sterilization rate;

Process optimization and upgrading: Transform the airflow layout of the workshop, formulate standardized cleaning SOPs, introduce automated disinfection equipment, and block the environment for microbial breeding;

Step 3 Dynamic monitoring, long-term guarantee

Digital monitoring platform: Real-time monitoring of key indicators such as workshop temperature and humidity, colony count, and automatic warning of abnormal data;

Periodic re-inspection service: quarterly in-depth detection + monthly inspection, dynamic adjustment of prevention and control strategies to ensure that pollution does not rebound.

Why choose Fantong Bio?

Technical core: 10 years of focus on food industry disinfection;

Efficiency commitment: 24-hour emergency response, providing complete solutions;

Compliance guarantee: The solution complies with international standards such as HACCP and ISO 22000