Feed Plant Microbial Contamination Control

- Addtime: 2025-08-21 / View: 175

Feed safety is the cornerstone of animal health and the primary guarantee of food safety. With over a decade of experience in industrial disinfection, Fantong Biotech has built a comprehensive microbial contamination control system for feed companies, from raw materials to finished products, leveraging precise detection technologies, customized prevention and control solutions, and a long-term management system. We help customers achieve the dual goals of quality improvement and risk management.

Microbial Contamination Risks and Hazards in Feed Production

Microbial contamination lurks throughout the entire production process, posing a significant threat:

Raw materials: Grains and fishmeal are susceptible to mold and salmonella contamination, and transportation residues can cause cross-infection.

Processing: Inadequate pelleting temperatures lead to incomplete sterilization, fungus can grow in equipment crevices, and humidity in workshops accelerates microbial growth.

Personnel: Inadequate protective equipment and lack of disinfection procedures can lead to direct contamination of feed by pathogens on the body.

Contamination not only leads to nutrient loss in feed, diarrhea, or growth retardation in animals, but can also threaten human health through the food chain, severely damaging a company's reputation and economic performance.

Fantong Solution: Accurate Traceability, Targeted Disinfection, and Long-Term Control

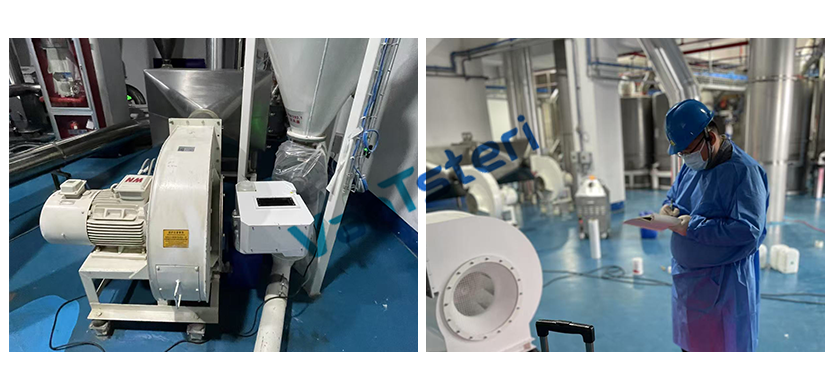

Step 1: Intelligent Detection, Precise Traceability

Molecular Biology Technologies: Utilize 16S rRNA gene sequencing and fungal ITS sequence analysis to rapidly identify pathogenic microorganisms such as Aspergillus flavus and Salmonella, as well as their toxin risks.

Three-Dimensional Environmental Sampling: Covers key locations such as raw material warehouses, processing equipment, air, and employee hands, combining temperature and humidity data analysis to precisely locate the source of contamination.

Step 2: Full-Process Targeted Disinfection to Prevent the Spread of Contamination.

High-Efficiency Sterilization Technologies: Utilize internationally certified technologies such as hydrogen peroxide vaporization based on contamination type, penetrating equipment gaps and dusty environments to achieve a sterilization rate of ≥99.99%.

Process Upgrade and Optimization: Optimize pelletizing temperature parameters, improve equipment cleaning procedures, and add automated disinfection equipment to disrupt microbial growth.

Strict Raw Material Control: Collaborate with suppliers to establish a microbial sampling mechanism and conduct secondary testing on high-risk raw materials (such as fish meal) to reduce contamination at the source.

Step 3: Dynamic Monitoring, Long-Term Guarantee

Digital Monitoring Platform: Real-time tracking of core indicators such as workshop temperature, humidity, and total bacterial count, providing instant alerts for abnormal data.

Periodic Re-inspection Service: Monthly inspections and quarterly in-depth testing dynamically adjust disinfection frequency and process parameters to ensure continued compliance with the "Feed Hygiene Standards."

Four Core Advantages of Choosing Fantong Bio:

✅ Core Technology: 10 years of dedicated expertise in feed industry disinfection.

✅ Accurate and Efficient: 24-hour emergency response.

✅ Compliance Assurance: Solutions comply with international standards such as ISO 22000 and HACCP, helping companies obtain authoritative certifications.

✅ Cost Control: Reduce product scrap rates through preventive disinfection and process optimization.

From source to end-user, Fantong Bio safeguards feed safety!