Pharmaceutical factory environmental disinfection

- Addtime: 2025-07-15 / View: 333

Article 45 of the 2010 GMP stipulates that, when necessary, fumigation may be used to reduce microbial contamination in sanitary blind spots within clean areas, and the residual level of the fumigant must be verified. The "2010 GMP FAQs" commentary on the "Disinfection Challenges in Clean Areas" states: "More and more companies are adopting hydrogen peroxide vapor disinfection. Sterilization effectiveness can be verified, and residual levels are easily tested."

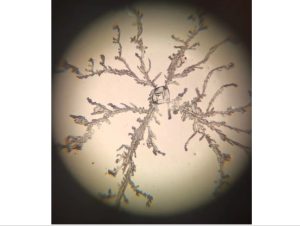

The 2023 GMP Guide states that according to the 2023 GMP Guide: HVAC Systems, it is recommended to regularly or temporarily reduce the microbial load in production areas or HVAC systems. Traditional methods cannot perform high-level terminal disinfection on pipes. Currently, there are pipe disinfection robots and terminal disinfection technology service providers. Fantong Biotechnology Company disinfects central air conditioning pipes in accordance with GMP requirements using high-level disinfectants. The robot enters the ducts and uses vaporization technology to seal and disinfect the ducts, killing bacteria and viruses. This technology is currently leading in China.

Fantong vaporized hydrogen peroxide disinfection, a GMP-compliant, efficient, safe, and residue-free disinfection method, is becoming an increasingly popular disinfection method for pharmaceutical companies. Fantong Bio can formulate targeted disinfection technology plans, arrange corresponding equipment and disinfection processes according to the characteristics of different production functional areas and air-conditioning systems, and completely solve the disinfection problems of clean areas.

Fantong Bio provides: integrated solution for disinfection and sterilization of clean workshops in pharmaceutical factories

Welcome to consult, Fantong Bio's engineers will develop targeted disinfection plans based on the requirements of your production area.